Experience on SEE testing EEE parts (Memories, RF Power devices…)

- Many basic testers availables which offer the capability to carry out a test in a rather short delay (a few weeks) at a relatively low cost.

- Capability to develop on demand test setup for complex devices (μP High frequency devices, RF fixtures etc…) higher cost driven by the test preparation effort.

- Access to many facilities, selection is based on more than 15 years of experience .

- In house device opening capability especially for plastic packages more and more difficult.

- Good electronics skills are mandatory for test setup development as well as a good knowledge of the tested device.

Wacth full presentation online here

Speakers:

Christian Binois (ADS) Mirko Rostewitz (TESAT) TSOEF1 -EEE Parts Engineering & Radiation

AIRBUS DS Test Activity Overview

- More than 600 tests since 2003.

- Mainly dedicated to provide SEE behaviour of EEE devices used by any ADS project.

- Fully integrated within the procurment process at early level, traceability (man lot, factory etc…) avoid a huge number of tests.

- Some internal R&D activities as well as some funded by ESA, CNES and DLR.

- Support on request to external customers (mainly on ADS related projects).

Test benches

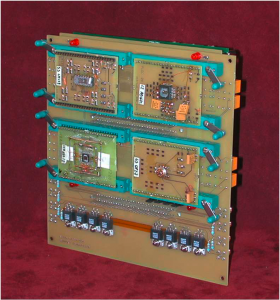

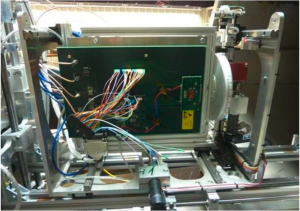

Generic test benches used for more than 90% of devices

- 4 test slots

Board compliant with all facilities.

Board compliant with all facilities.- Many remotely programmed analog and digital I/O

- High speed digitizers for SET

- Ability to test SEU, SET and SEL separately or at the same time depending on the device

- Ability to test Opamps, comparators, voltage ref and regulator, DAC, ADC and the most current digital circuits (line buffer, latches etc…)

- Ease of daughter board design (a few days)

- Capability to change quickly test conditions during test

- Autotest to check device and tester good healt

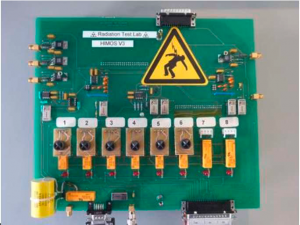

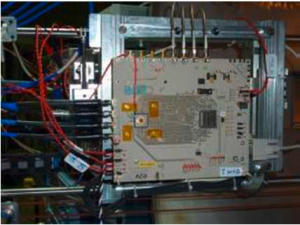

- 8 test slots

- Can hold P or N channel up to 600V Vds and +/-100V Vgs

- On line measurement of Igss (10pA to 100mA) and Idss

- SEB detection and Drain charge collection integrated acquisitions

- Integrated VGSth measurement for N channel (P to be added)

- Integrated PIGST capability

- Fully Remote controlled operation

- Integrated autotest to check device connection and tester integrity before irradiation ( a not connected device is seen unsensitive )

- 8 test slots

Up to 1100V VR (design limit 7.5kV)

Up to 1100V VR (design limit 7.5kV)- Temperature monitoring with heating option

- On line measurement of Ir(10pA to 20mA)

- Remote controlled operation

- Integrated autotest to check device and tester integrity before irradiation ( a not connected device is seen unsensitive )

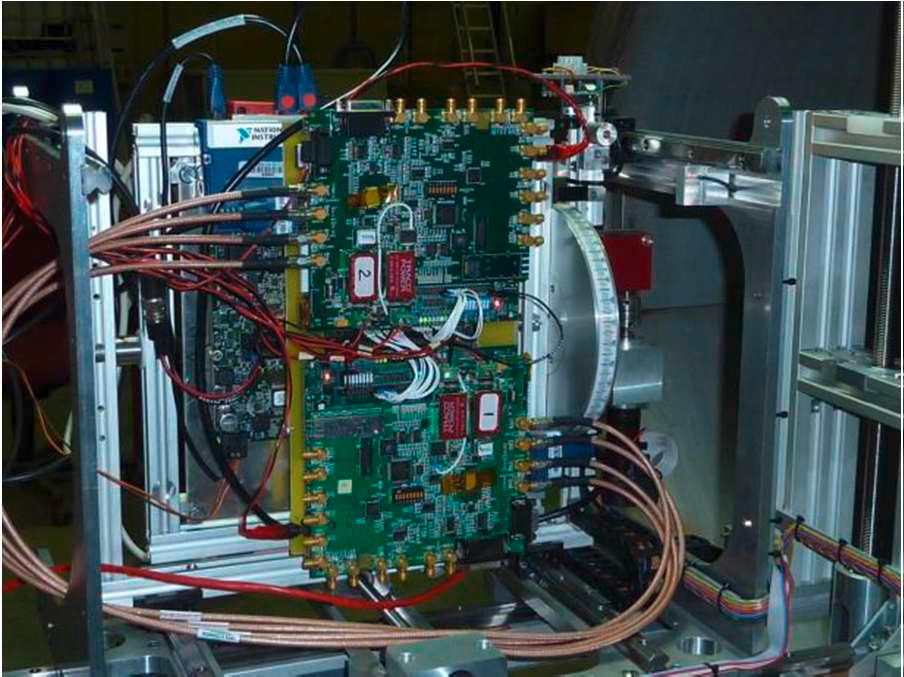

- 40 MHz asynchronous mode & 20 MHz synchronous DDR

mode

mode - 2 adjustable protected supplies (SEL) with on line voltage and current monitoring

- Embedded Processor under Linux RT and FPGA

- Remote controlled operation through single ethernet link

- Integrated hard drive for high speed data recording (many Gbytes of data during test)

- User defined test sequence up to 2000 cmd/s

One shot test benches

- SET detection with High Frequency dynamic signals, (400MHz with 3GHz carrier ) no Scope trigger usable —dedicated analog trigger designed

- 4 output modes

- SEL assesment for Delatcher design

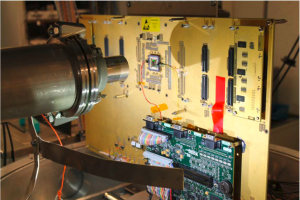

- Full speed operation at 6.6Mpix/s

- Image to image comparison for SET detection on pixel (>14mV)

- Removable optical stimuli to check device functionnality (vacuum mandatory)

- 300 MO/s to be checked on line

- Difficult to manage gigabit connexions and PCB

- Rx/TX synchronisation (many bits stored in the Tx line)

- Many elementary tests to cover all functionnal units

- High workload for test development and data analysis after test

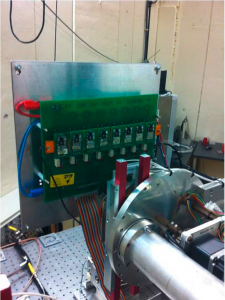

RF SEE Testing

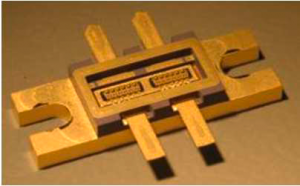

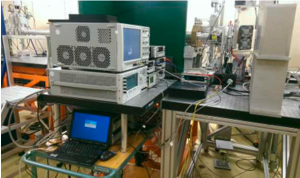

- E.g. “Qualification of GaN Power Bars for BIOMASS” with the ESA contract No. 4000110760/14/NL/CT

- 15 and 80 W RF GaN power devices from UMS

- In-air facility is needed due to the high heat dissipation

• KVI – center of advanced radiation technology at the University of Groningen (The Netherlands)

• In air beam line with 29 MeV/amu

- Complex RF Test Setup

- High RF Power handling capability

- Peltier Cooling Unit

- Remote control capability

Download or read the full report here

GDE Error: No se ha podido cargar el perfil solicitado.

Últimas entradas de Media ATN (ver todo)

- Inmunidad conducida - 20th mayo 2019

- Ensayos de Transitorios eléctricos - 2nd mayo 2019

- Ensayo Campo de RF radiado - 2nd mayo 2019