Improper degree of compression

Stress relaxation:

This induces a significant decrease of the contact pressure held between the wires and at the wire-barrel interface, which in turn increases the contact the resistance. Such phenomena, either creep flow or recrystallization processes, are not spontaneous and requires high temperatures. For instance, Cu recrystallization is induced at temperatures higher than 120 ºC whereas Cu creeping requires higher temperatures.

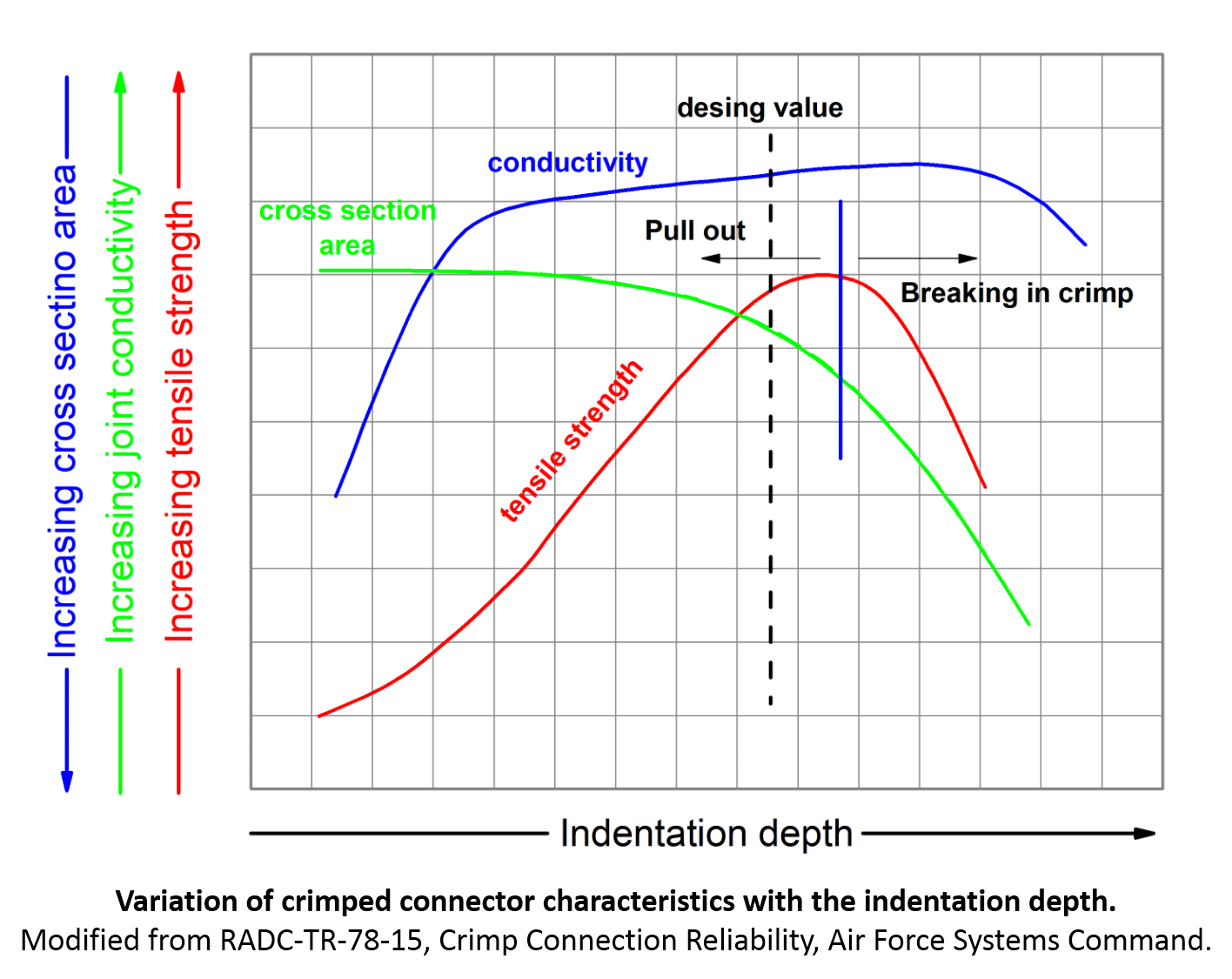

Care should be taken neither to damage the insulation of the wire strands nor to leave insulator residues over the stripped conductor. Crimping must be performed according to the manufacturers specification and especial attention must be paid to the barrel and wire compatibility, as well as the suitability and calibration of the crimping tool that determines the applied force and the reached insertion depth. Failure to follow the manufactures specifications results in poor crimping with negative effects in both the mechanical strength and the contact conductivity as illustrated in the figure.

Diagnosis tools:

In general, improper degree of compression and related issues can be detected either by mechanical test such as tensile strength test and metallographic cross-section inspection of the crimped area. In the latter case a comprehensive inspection must check several factors: the void percentage, the barrel and wires deformation, braids distribution and the barrel and wire integrity. The figure compares crimped connectors analyzed in our laboratory. One of the examples show a large percentage of void area which is indication of low degree of compression and poor electrical contact as well as a rejection cause according to the specification ECSS-Q-ST-70-26C, applied in European Space Agency (ESA) projects.

Inspection conducted in our laboratory.

Inspection conducted in our laboratory.

Examples of Connectors rejected and accepted iaw the specification ECSS-Q-ST-70-26C

Failures in crimped connectors can be can be related to different causes, some of the discussed elsewhere. The present post analyzes those related to improper degree of compression.

Contact us

- Scanning Acoustic Microscopy on Ceramic Capacitors - 18th May 2020

- Non-destructive detection of micrometric internal features within EEE microelectronic systems. - 3rd September 2019

- Acoustic Inspection of Hybrid Systems on Laminated Substrates - 3rd September 2019