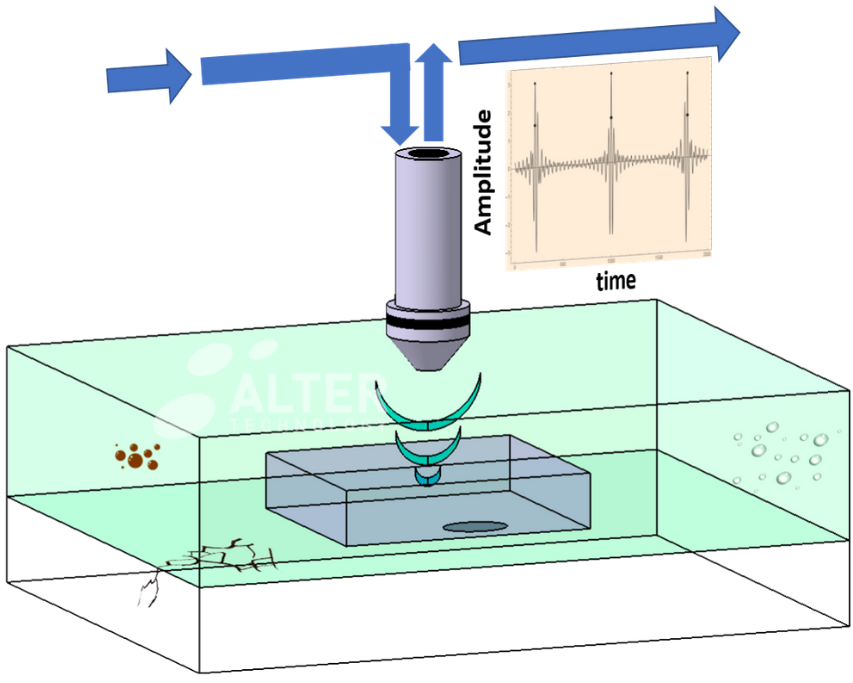

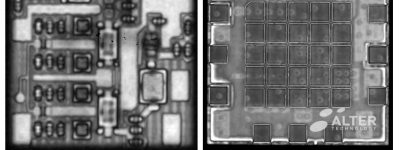

Scanning acoustic microscopy (SAM) also denominated acoustic micro imaging (AMI) and scanning acoustic tomography (SAT) is a consolidated and recognized tool for quality control, inspection and failure analysis of microelectronic components and materials.

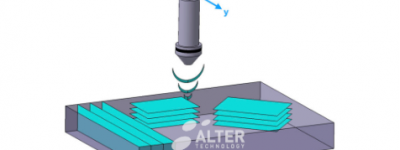

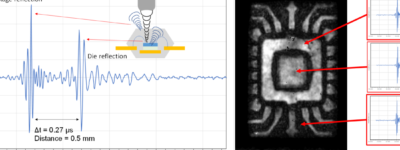

The working principle of the technique is based on the reflection that acoustic waves experience at the interface between different media and density irregularities. Thus, the approach makes use of focalized ultrasound (MHz to GHz) pulses to image material interfaces and boundaries as well as hidden physical damages, either generated during manufacturing or induced after environmental testing and prolonged normal operation.

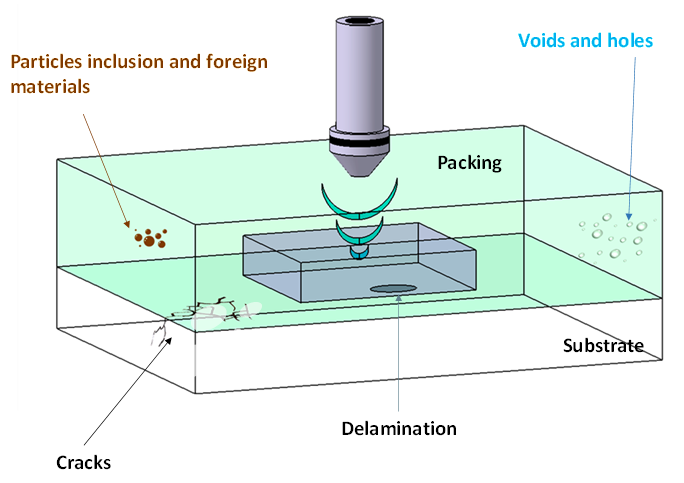

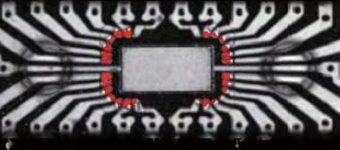

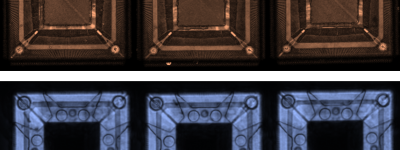

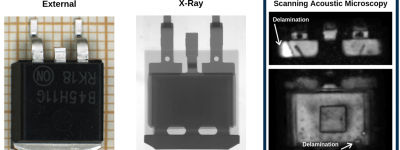

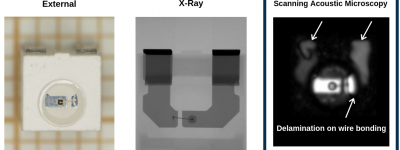

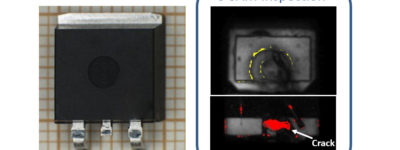

As illustrated in the figure, the technique is routinely used for the nondestructive detection of internal flaws such as:

Detected failures

In/through

Materials

- Delaminations

- Voids and porosity

- Cracks

- Particles inclusions and foreign materials

- …

- Packing materials including mold compouds

- Semiconductors

- Ceramics and glasses

- Adhesives (e.g. underfills)

- Metals

Hence, during the last decades, SAM has proved to be a reliable and powerful tool for the non-destructive inspection in different sectors such as:

- Space

- Defense and Aerospace

- Automotive

- Power and energy

- Martials analysis: ceramics and composites

Our test services and target applications include.

Main activities and services

Our test services and target applications include.

- Reliability test

- Quality Control / Screening task.

- Preliminary non-destructive inspection in DPAs

- Failures analyses.

Conducted according to different test methods such as:

- ESCC 25200 “Application of Scanning Acoustic Microscopy to Plastic Encapsulated Devices”

- IPC JEDEC J-STD-020 Moisture/Reflow Sensitivity Classification for Nonhermetic Surface Mount Devices

- J-STD-035 Acoustic Microscopy for Nonhermetic Encapsulated Componentes

- MIL-STD-883 “Test Method 2030 “Ultrasonic Inspection of die attach”

- MIL-STD-1580 “Destructive Physical Analysis for Electronic Electromagnetic and Electromechanical Parts”

- NASA PEM-INST-001 “Instructions for Plastic Encapsulated Microcircuit (PEM) Selection, Screening, and Qualification” (NASA/TP—2003–2122)

REAL TIME FEEDBACK

Our Vitual Lab platform for Remote Testing provides Alter Technology users with:

- Instant access to test results

- Live chat with our inspectors during and after test duration

- Access to Alter Technology data base (30 years of accumulated data) for performance comparison with other batches and similar components.

Thanks to the Virtual Lab tool the customer can devise his own test solution specifically adapted to the actual needs and requirements and monitor test results in real time, without the need to wait for the completion of all the activities. Therefore, the final user can adapt the inspection areas and planes depending on the initial results. He will also receive feedback and advice from our test engineers during or thereupon inspection.

Detailed inspection records can be accessed immediately after the activity completion. Thus, manufacturers and users gain valuable time to develop contingency plans and solutions to address detected anomalies.

Complementary inspection techniques

Stress test

- Humidity, moisture and thermal test.

- Thermal-vacuum testing

- Temperature cycling

- Thermal shock

- Vibration testing

Our commitment to quality

In Alter Technology the Scanning Acoustic Microscopy Lab involves a qualified (Ph.D., M.Sc.) and multidisciplinary team specialized in different disciplines such as Materials Science, Physics, Electronics, and Aerospace Engineering; together with a highly experienced technical staff with a solid background in microscopy, materials analysis and EEE inspection. This team is supported by more than 30 years of experience of Alter Technology in EEE testing and engineering.