The objective of life testing is to evaluate whether failures caused by wear-out are likely to occur during the product lifetime and thus to estimate compliance of the device with the long-term reliability requirements. Continue reading

This type of inspection is performed using an electron microscope which produces images of a sample by scanning it with a focused electron beam. Interaction between the electrons and atoms in the sample generates signals that contain information about the sample’s surface... Continue reading

The purpose of the seal test is to determine the effectiveness of the sealing of components with internal cavities, i.e. to determine their hermeticity. Defective sealing may permit the entrance of contaminants, thus reducing the effective life and reliability of devices. Continue reading

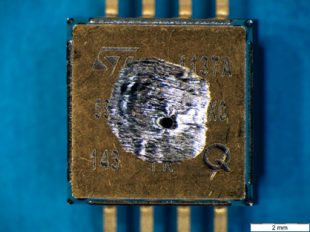

The purpose of radiographic inspection is to detect internal physical defects which are not otherwise visible in electronic components. The radiographic techniques reveal such flaws as presence of foreign objects, improper interconnecting wires, inhomogeneities in materials... Continue reading

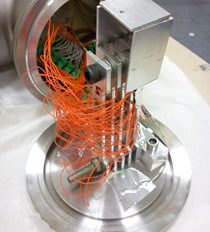

The purpose of vibration tests is to evaluate the effect caused on component parts by vibration in a specified frequency range. The samples are subjected to testing under different conditions, as described below, in accordance with the respective applicable standards. The test... Continue reading

Electronic Components Thermal shock testing is performed to determine the ability of parts to function properly in an environment with sudden extreme changes in temperature. It is also used for accelerated testing during product evaluation and qualification process. Thermal... Continue reading

Environmental testing provides a useful tool for evaluation, qualification and screening of EEE components for high-reliability applications. Various types of stresses can be applied to the products in a controlled manner thus allowing to accelerate the appearance of latent... Continue reading

Residual Gas Analysis, also known as Internal Gas Analysis (IGA), is a destructive test which is performed to examine the atmosphere inside hermetically sealed devices. The test procedure is based on milling the component so that the gas content can be extracted and subsequently... Continue reading

determine the ability of parts and solder interconnects to resist extremely low and extremely high temperatures, as well as their ability to endure cyclical exposures to temperature extremes. Permanent changes to the electrical or physical characteristics of the devices under... Continue reading

Under certain conditions and in accordance with the ECSS-Q-ST-60-13C standard on the use of commercial EEE parts in space applications, this test may be replaced by the Highly Accelerated Stress Test (HAST) with the test duration reduced to 96 hours. See HAST page for further... Continue reading

The aim of this process is to verify the conformity of the exterior of electrical, electronic and electromechanical components (EEE parts) with the acquisition document. The following aspects should be considered: Marking Aspect of Materials Workmanship Sealing Leads Feedthroughs Continue reading

This analytic technique may provide both qualitative and quantitative information of the composition of a surface, i.e. identification of the elements and the element weights, respectively. The technique relies on the detection and spectroscopy of secondary radiation (X-Ray)... Continue reading