Surface contamination involving micrometric particles, microbiological agents, molecular adsorbate and others, represent a significant hazard in many areas of industry. For instance, a high level cleanliness is a critical requirement that any EEE device has to fulfil at any... Continue reading

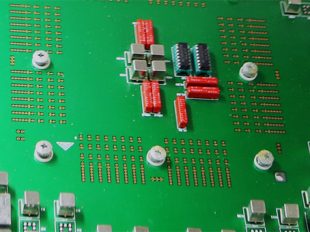

The procurement, evaluation, screening and lot acceptance of RF devices in leadless SMD packages to be used in spacecraft applications show unexpected difficulties whenever degolding or retinning processes are required. This is associated to the induced lack of coplanarity in... Continue reading

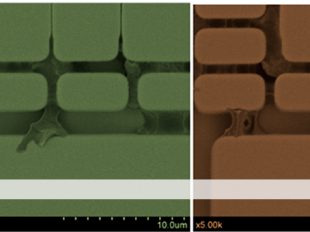

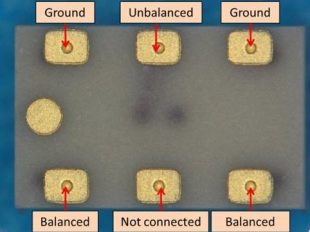

A compact balanced-to-balanced diplexer composed of two balanced bandpass filters is proposed in this letter. The balanced filters are implemented using compact edge-coupled square split-ring resonators. The design methodology is based on the standard coupled-resonators filter... Continue reading

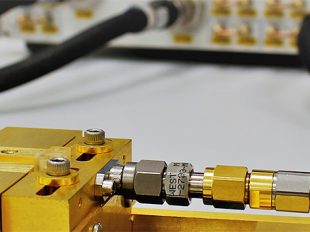

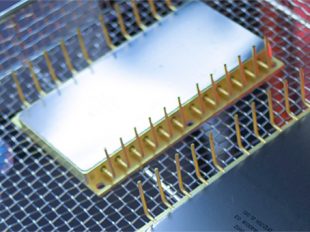

SOLDERLESS MEASUREMENTS ON MICROWAVE. Screening activities for space applications requires extreme care during the manipulation of the EEE parts to be assembled on a spacecraft. This means that special attention shall be paid to avoid damages on the pieces and any contamination... Continue reading

Material Analysis is performed to detect and identify the materials used in the manufacturing of semiconductors and microelectronic parts and packages. One particular use of this analysis is the detection of prohibited materials, especially in the lead finish, to identify... Continue reading

The reliability of the components used in a spacecraft is a determinating factor for their operation and performance throughout the mission life. Only the most advanced techniques are able to provide the depth and accuracy in the inspections required by current state of the art... Continue reading

Long Term Storage EEE components We have extensive experience in EEE parts engineering, procurement and storage. Long Term Storage was one of our early studies. In 1993, in the frame of COLUMBUS project, we got an ESA contract to assess the “Long Term Storage for High... Continue reading

Fully compliant with the project requirements Our commercial and technical expertise and experience allows us to recommend, select and supply components from good manufacturing sources (avoiding counterfeits). All EEE parts procured by us are fully inspected and tested to ensure... Continue reading

In-house capacity, capability and expertise to perform electrical screening of any type of electronic component technology. For passive devices testing, we have equipment which permits the characterization of the electrical behavior of resistors, capacitors, coils, etc., in a... Continue reading

The purpose of the inspection is to detect: Manufacturer deviations Handling damages that could affect the device assembly and its final application Continue reading

The purpose of this test is to verify that the markings on component parts will not become illegible when subjected to solvents (e.g. during the board cleaning process after parts assembly) or during normal handling, and that the solvents employed for the test will not cause... Continue reading

PIND ( Particle Impact Noise Detection Test ) testing is performed in order to detect the presence of loose particles inside a device cavity. Loose particle contamination is often caused by dirt, fibers, solder residues and other elements trapped inside the cavity during the... Continue reading