Material Analysis is performed to detect and identify the materials used in the manufacturing of semiconductors and microelectronic parts and packages. One particular use of this analysis is the detection of prohibited materials, especially in the lead finish, to identify... Continue reading

PIND ( Particle Impact Noise Detection Test ) testing is performed in order to detect the presence of loose particles inside a device cavity. Loose particle contamination is often caused by dirt, fibers, solder residues and other elements trapped inside the cavity during the... Continue reading

The purpose of the seal test is to determine the effectiveness of the sealing of components with internal cavities, i.e. to determine their hermeticity. Defective sealing may permit the entrance of contaminants, thus reducing the effective life and reliability of devices. Continue reading

The purpose of radiographic inspection is to detect internal physical defects which are not otherwise visible in electronic components. The radiographic techniques reveal such flaws as presence of foreign objects, improper interconnecting wires, inhomogeneities in materials... Continue reading

The purpose of vibration tests is to evaluate the effect caused on component parts by vibration in a specified frequency range. The samples are subjected to testing under different conditions, as described below, in accordance with the respective applicable standards. The test... Continue reading

Under certain conditions and in accordance with the ECSS-Q-ST-60-13C standard on the use of commercial EEE parts in space applications, this test may be replaced by the Highly Accelerated Stress Test (HAST) with the test duration reduced to 96 hours. See HAST page for further... Continue reading

The aim of this process is to verify the conformity of the exterior of electrical, electronic and electromechanical components (EEE parts) with the acquisition document. The following aspects should be considered: Marking Aspect of Materials Workmanship Sealing Leads Feedthroughs Continue reading

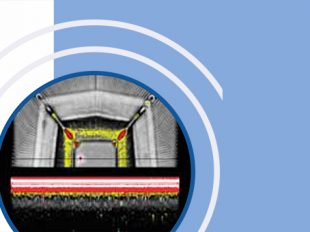

Scanning Acoustic Microscopy (SAM) is an inspection that uses focused sound to investigate, measure, or obtain an internal image of an object. It is commonly used in failure analysis and non-destructive evaluation. The semiconductor industry has found the SAM, particularly the C... Continue reading

Lead integrity test is performed to determine the integrity of the device leads (terminals), welds and seals. During the execution of this test, the DUT is subjected to various stresses including tension, bending fatigue and torque. The stresses to be applied depend on the DUT... Continue reading

is performed to evaluate the reliability of non-hermetic packaged solid-state devices that are likely to encounter humid environments during normal (ambient) operation. Also known as Pressure Cooker Test (PCT) or Unsaturated Pressure Cooker Test, the purpose of HAST is to... Continue reading

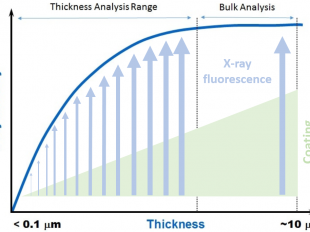

The thickness of metallic coatings is routinely determined by X-ray fluorescence spectrometry. This provides a basis for assessing the quality of coated materials and therefore influences decisions regarding disposition (acceptability) of coated product as well as control of... Continue reading

Burn-in test is an electrical stress test that employs voltage and temperature to accelerate the electrical failure of a device. Continue reading