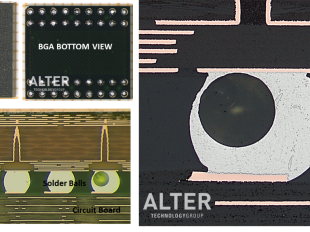

BGA device assembled to a PCB has been submitted to the ECSS verification programme following the guideline defined in the ECSS standard ECSS-Q-ST-70-38C. Continue reading

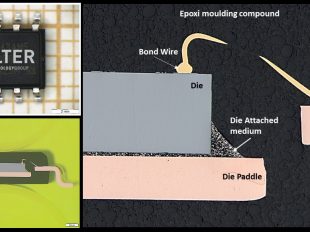

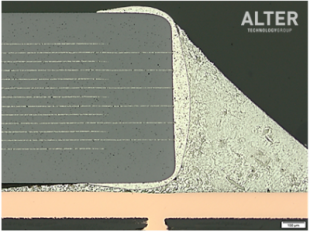

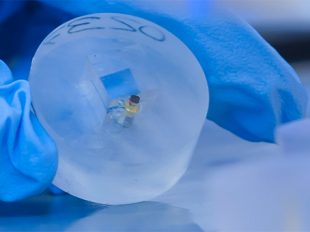

Cross-section analysis is a very useful way of determining the construction and material composition of electronic devices. The FP device is potted in epoxy resin. After curing, the sample is sequentially grinded up to reach the plane of interest. Then, the specimen is subjected... Continue reading

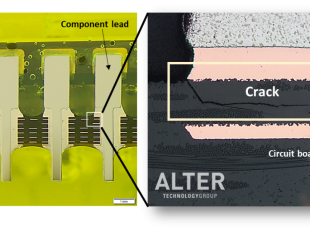

Microsection analysis is performed on an assembled through-hole device as a part of failure analysis. Cross-section through the plane of interest can provide helpful information about solder defects, PCB inner layers, and internal construction. As a part of failure analysis, the... Continue reading

The separation of the interest area has to be performed in such a way as to prevent any damage by deformation or input of heat. After cleaning, the specimen is encapsulated before the grinding process takes place. Continue reading

Assembly process of THT or SMT onto PCBs for spacecraft applications follow well-established design requirements based on specifications prepared by ECSS (ECSS-Q-ST-70-08C & ECSS-Q-ST-70-38C), NASA and IPC (IPC-6012). Continue reading

Resistors assembled to a PCB have been submitted to the ECSS verification program. Metallographic analysis allows us to check the status of such devices after performing the environmental tests (Vibration & Thermal Cycling). Continue reading

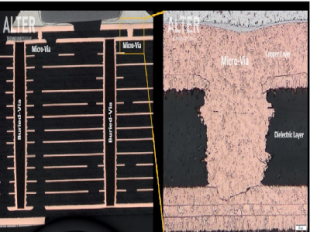

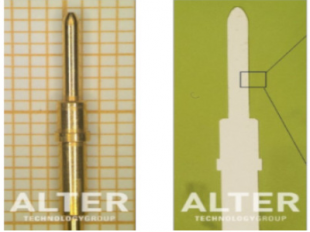

Cross-sectioned pins were metallographic prepared in ALTER TECHNOLOGY Materials & Processes Laboratory, recognized as a recommended facility for such activity by ESA authority (MEMO ESA-TECMSP-MO-013165). Continue reading

Cross-sectioned ceramic capacitors were metallographically prepared in the Materials & Processes Laboratory, recognized as a recommended facility for such activity by the ESA authority (MEMO ESA-TECMSP-MO-013165). Continue reading

Microsectioning and materialographic inspection are mandatory in different verification and qualification standards issued by international agencies and public bodies such as the European Space Agency (ESA), the Defense and Logistics Agency (MIL DLA specifications) and the IPC... Continue reading

The purpose of radiographic inspection is to detect internal physical defects which are not otherwise visible in electronic components. The radiographic techniques reveal such flaws as presence of foreign objects, improper interconnecting wires, inhomogeneities in materials... Continue reading

The cross-sectioning process provides access to the device internal structure, its materials and design. Such components as diodes and capacitors and silicon dice are often subjected to cross-sectioning to detect the defects which could not be found using other testing... Continue reading